Introduction:

OLED (Organic Light-Emitting Diode) displays are renowned for their vibrant colors, high contrast ratios, and energy efficiency. However, behind this cutting-edge technology, SCF (Screen Cooling Film) plays a vital role in electrical connectivity. At the heart of SCF lies copper foil, a material crucial for ensuring the seamless operation and performance of OLED displays.

Significance of SCF in OLED Displays:

SCF technology revolutionizes the internal electrical signal transmission in OLED displays. By employing SCF, the efficiency of charge carrier injection into the organic layers of OLED is significantly improved, resulting in enhanced brightness, color accuracy, and overall display quality. This technology not only optimizes performance but also contributes to energy savings, making OLED displays more appealing for various applications.

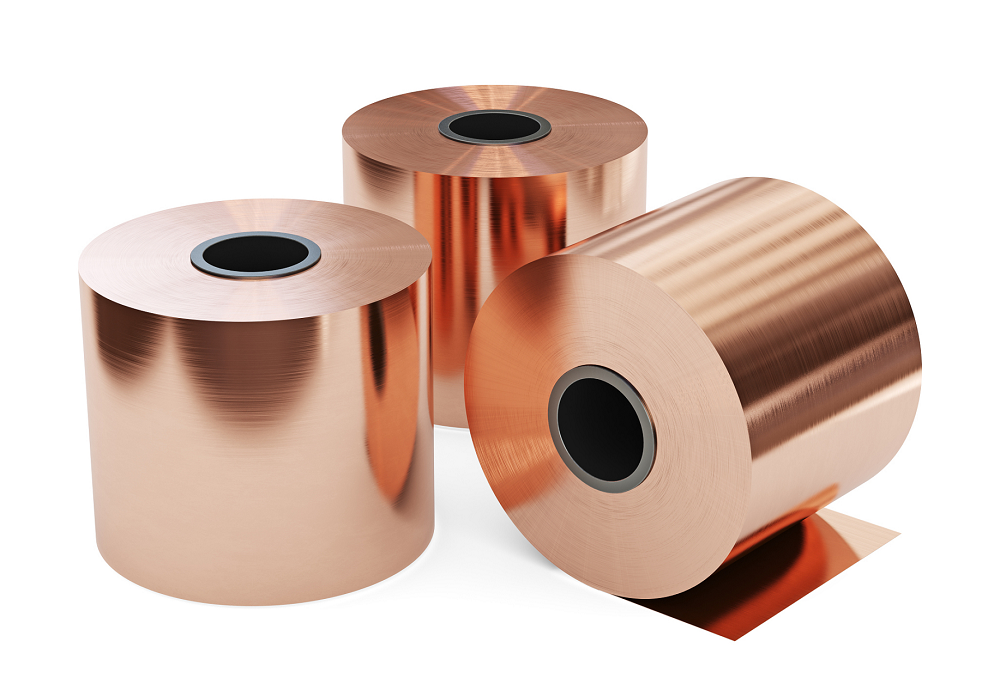

Copper Foil: Key Component of SCF:

Copper foil serves as a vital component in SCF technology, ensuring efficient electrical connectivity within OLED displays. With its excellent conductivity, copper foil facilitates the transmission of electrical signals with minimal resistance, ensuring fast and reliable communication between different components of the display module. Moreover, its flexibility allows it to conform to the complex designs and layouts of OLED displays, facilitating seamless integration and assembly.

Manufacturing Process:

The production of SCF for OLED displays involves intricate manufacturing processes, with copper foil playing a central role. Ultra-thin copper foils are carefully selected and prepared to meet the stringent requirements of OLED display production. These foils undergo precision etching and patterning processes to create intricate circuitry and interconnections necessary for SCF functionality. Advanced techniques such as roll-to-roll processing further streamline the manufacturing process, ensuring high throughput and cost-effectiveness.

Advantages of Civen Metal Copper Foil in SCF:

Civen Metal’s copper foil offers several advantages crucial for the successful implementation of SCF in OLED displays. Its high conductivity minimizes signal loss, ensuring efficient charge carrier injection and distribution throughout the display panel. Additionally, Civen Metal’s copper foil exhibits excellent thermal conductivity, aiding in heat dissipation and enhancing the longevity and reliability of OLED displays. Furthermore, its compatibility with existing manufacturing infrastructure facilitates seamless integration into OLED production lines, driving innovation and adoption in the display industry.

Future Perspectives:

As OLED technology continues to advance, the role of copper foil in SCF is poised to become even more significant. Ongoing research and development efforts aim to further enhance the performance and efficiency of OLED displays, with Civen Metal’s copper foil playing a vital role in realizing these advancements. Additionally, emerging applications such as flexible and transparent OLED displays present new opportunities for leveraging copper foil-based SCF technology, paving the way for innovative display solutions in diverse sectors.

Conclusion:

In the realm of OLED display production, SCF technology represents a groundbreaking advancement that relies heavily on the exceptional properties of copper foil. As a key component of SCF, Civen Metal’s copper foil enables efficient electrical connectivity, enhances display performance, and drives innovation in the display industry. With ongoing advancements and emerging applications, copper foil-based SCF technology is poised to continue shaping the future of OLED displays, offering unparalleled visual experiences and technological possibilities.

Post time: Mar-21-2024