-

01

Who are we?

Your expert in making metal materials and its related products.

-

02

What we make?

High and stable quality metal materials to make your products more competitive.

-

03

What’s new?

Always keeping our edge on the top and renewing ourselves.

-

04

How to contact?

Our products are adopted by most famous companies all over the world.

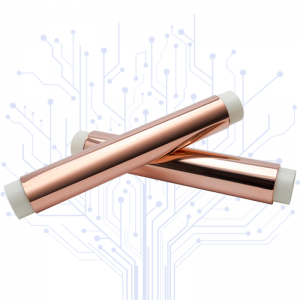

Hot Products

-

Policy

Guided by the market, guaranteed by quality.

-

Philosophy

Transcend ourselves and pursue excellence!

-

Style

Never giving today's work to tomorrow

-

Spirit

Sincere cooperation, innovation and challenge for the future.

Why Choose Us

-

Over 20 years of experience

CIVEN METAL established in 1998. We work at developing, producing and circulating metallic materials.

-

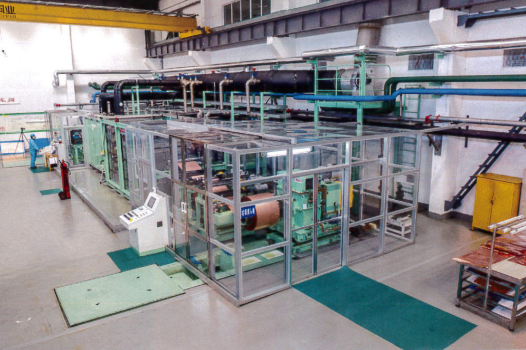

Advanced equipment

With the company healthy developing, we equip ourselves with advanced production equipments and high-tech measuring instruments. We continuously improve our technique and facilities to keep our edge in this industry.

-

Excellent R & D capability

Our R&D section has been working at the development of new metallic materials in order to enhance the core competence of the corporation.

We work at developing

producing and circulating metallic materials.

Please leave to us and we will be in touch within 24hours.

![[HTE] High Elongation ED Copper Foil](https://cdn.globalso.com/civen-inc/HTE-High-Elongation-ED-Copper-Foil-300x300.png)