Classification of ED copper foil:

1. According to the performance, ED copper foil can be divided into four types: STD, HD, HTE and ANN

2. According to the surface points, ED copper foil can be divided into four types: no surface treatment and no prevent rust, surface treatment of anti-corrosion, one-side processing anticorrosion and double dealing with corrosion prevention.

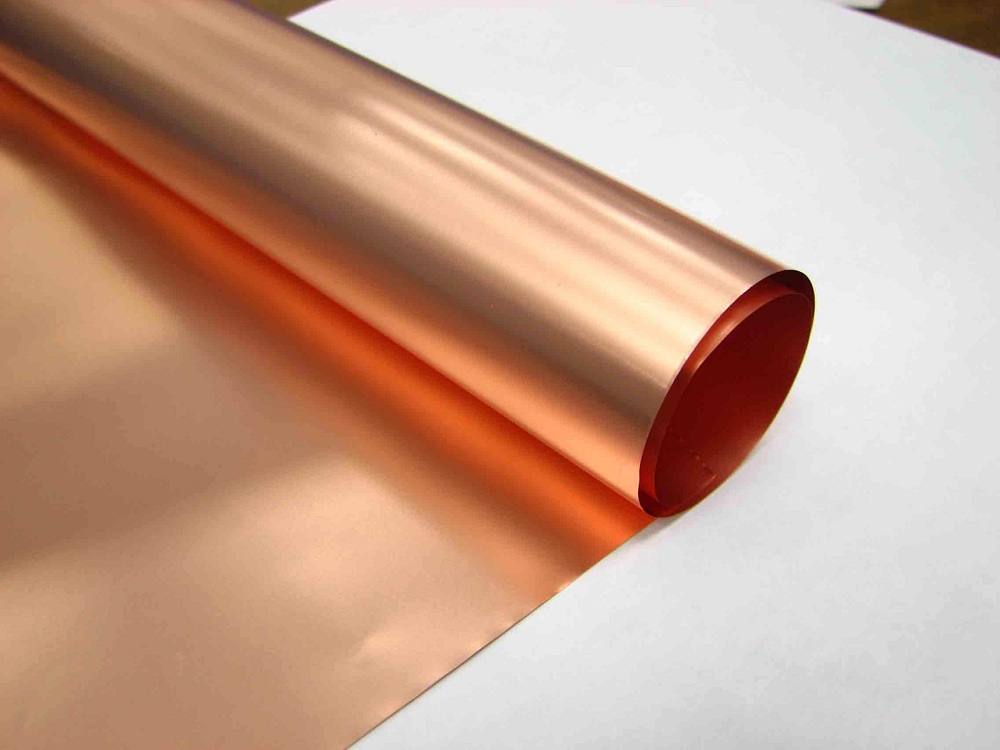

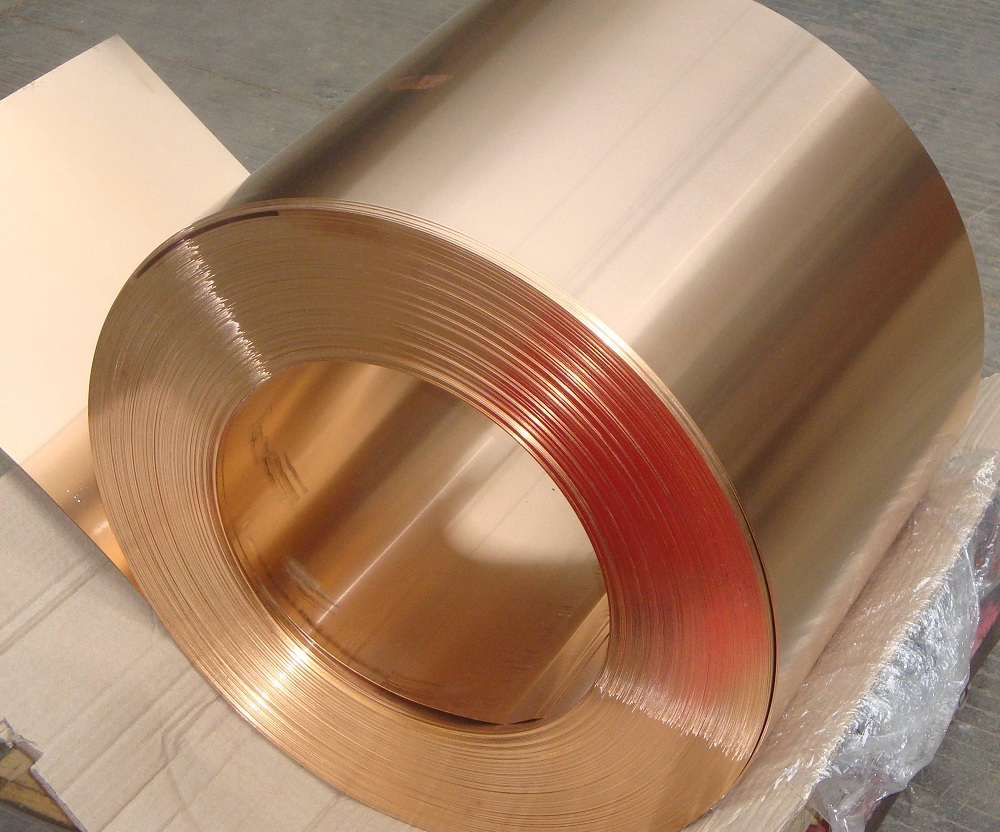

From the thickness direction, the nominal thickness of less than 12μm is thin electrolytic copper foil. To avoid the error on the thickness measurement, and weight per unit area is expressed such as the universal 18 and 35μm electrolytic copper foil, its single weight corresponding to 153 and 305g / m2. ED copper foil quality standards including purity electrolytic copper foil, resistivity, strength, elongation, weld ability, porosity, surface roughness, etc.

3. ED copper foil can be divided into the production process of preparing the electrolytic solution, electrolysis and post-processing according to electrolytic copper foil production technology.

Preparation of electrolyte:

First put the purity higher than 99.8% of copper material after degreasing tank into the copper dissolved; then cooking with sulfuric acid stirring and we get dissolved copper sulfate. Put the copper sulfate into the reservoir when the concentration reaches the requirements. It will come a solution circulation system through the pipeline and the pump reservoir and cell Unicom. After the solution circulation is stable, it can power the electrolysis cell. Electrolyte needed adding an appropriate amount of a surfactant to ensure particulate copper values , Crystal orientation, roughness, porosity, and other indicators.

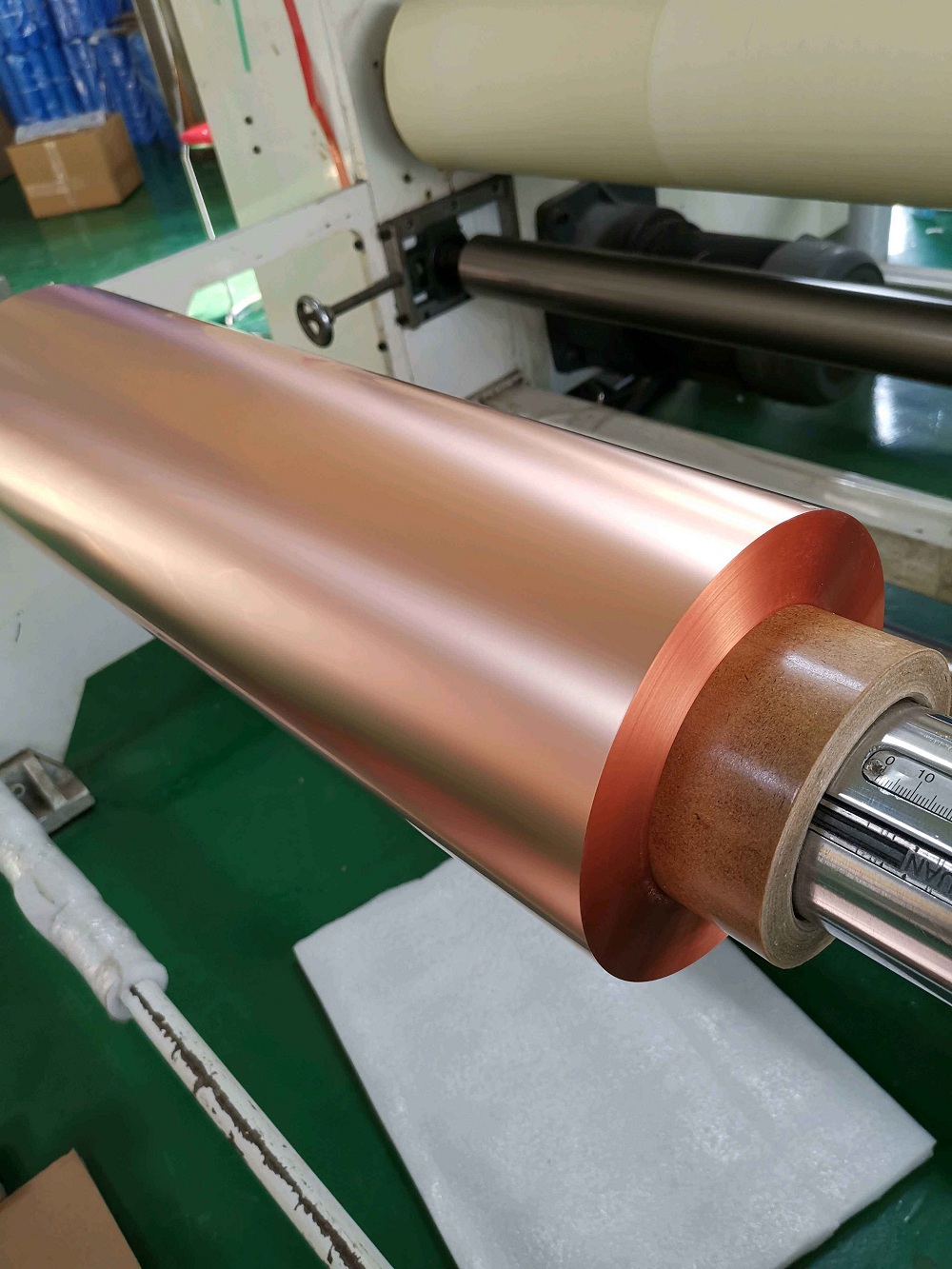

The process of electrodes and electrolysis

Electrolysis cathode is a rotatable drum, called cathode roll. And it also can use available mobile headless metal strip as a cathode. It begin deposited on copper cathode after power. Therefore, the width of the wheel and the belt determines the width of electrolytic copper foil; and rotating or moving speed determines the thickness of the electrolytic copper foil. Copper deposited on the cathode is continuously peeled off, cleaning, drying, cutting, coiling and testing after treatment sent to successful applicants. An electrolysis anode is insoluble of lead or lead alloy.

Process parameter is not only related with the speed of electrolysis the cathode, but also with the electrolyte solution or the concentration, temperature, cathode current density during electrolysis.

Process parameter is not only related with the speed of electrolysis the cathode, but also with the electrolyte solution or the concentration, temperature, cathode current density during electrolysis.

A titanium cathode roller spinning :

Because of titanium has high chemical stability and high strength. It easily peels from the roll surface and low porosity for electrolytic copper foil. Titanium cathode in the electrolytic process will produce passive phenomenon, therefore requiring regular cleaning , grinding , polishing, nickel , chrome. Corrosion inhibitors may also be added , such as nitro or nitrous aromatic or aliphatic compounds to the electrolyte , the passivation rate slows titanium cathode .Also some companies use the stainless steel cathode to reduce the cost .

Post time: Jan-09-2022