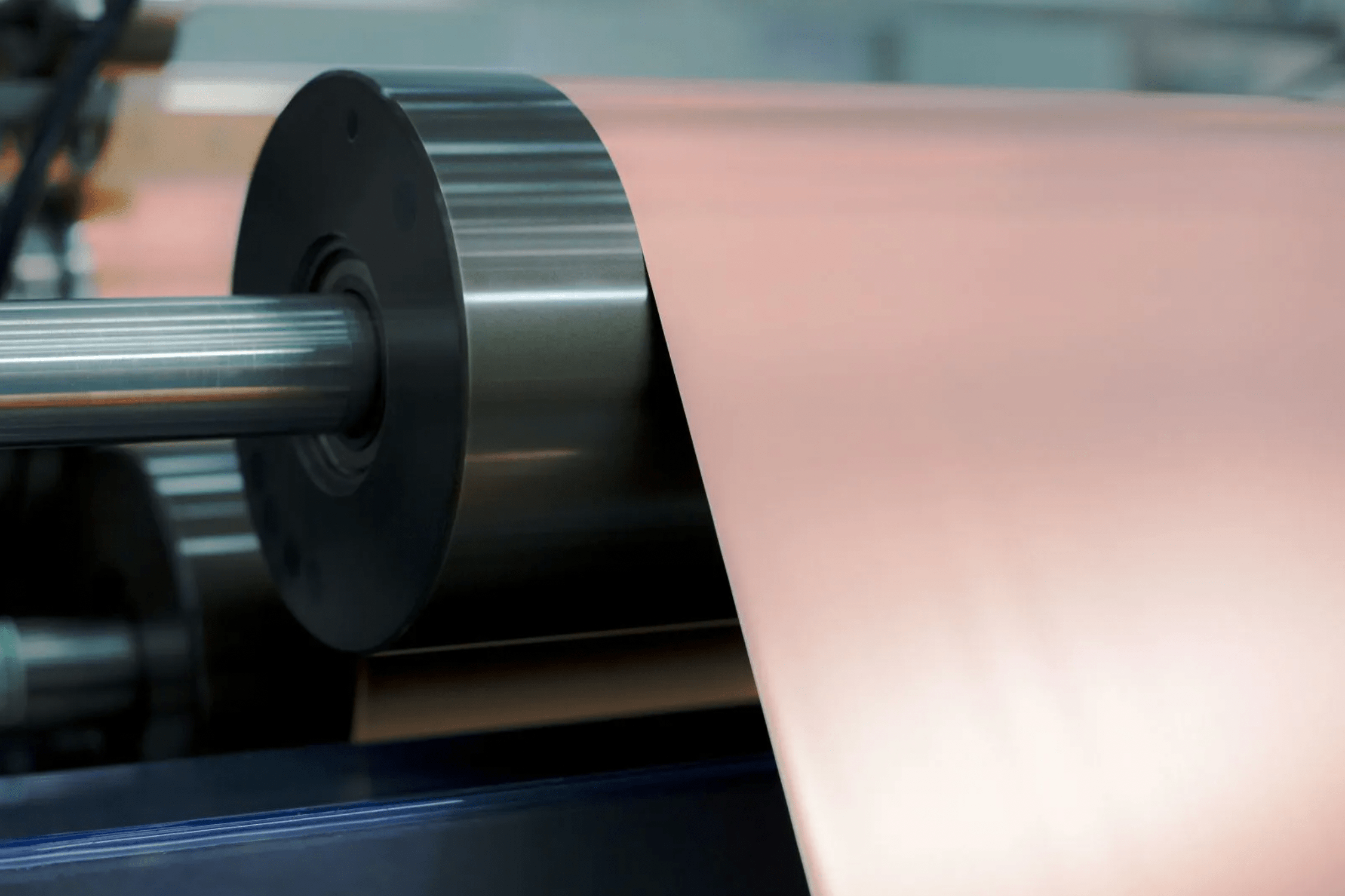

The application of copper foil in plate heat exchangers has become a popular choice mainly due to the excellent properties of high thermal conductivity and corrosion resistance, which are essential for plate heat exchangers.

Plate heat exchangers are a commonly used heat exchange device in industrial fields, which can exchange heat between liquids or gases by installing copper foil and other materials on the plate. Copper foil plays a critical role in this process by improving heat transfer efficiency, and ensuring equipment stability and reliability.

Copper foil has excellent thermal conductivity, far exceeding many other materials, making it an ideal material for plate heat exchangers. As copper foil can quickly transfer heat from one place to another, the overall efficiency of the heat exchanger is improved, while also reducing energy waste.

In addition, copper foil has good corrosion resistance, which can withstand corrosion from various chemicals, making plate heat exchangers able to work in harsh environments and extending the equipment’s service life.

CIVEN METAL is a professional copper foil manufacturer that provides high-quality copper foil materials for the application of plate heat exchangers. The company uses high-quality copper ingots as raw materials, and ensures the production of copper foil that meets the highest standards of quality and performance requirements through advanced production technology and strict quality control.

In conclusion, the application of copper foil in plate heat exchangers is significant. With its excellent thermal conductivity and corrosion resistance properties, copper foil can significantly improve the heat transfer efficiency and reliability of plate heat exchangers. CIVEN METAL’s copper foil materials provide high-quality solutions for the application of plate heat exchangers, providing customers with excellent performance and reliability.

Post time: Mar-07-2023