2021 Good Quality Copper Sheet - Bronze Strip – CIVEN

2021 Good Quality Copper Sheet - Bronze Strip – CIVEN Detail:

Product Introduction

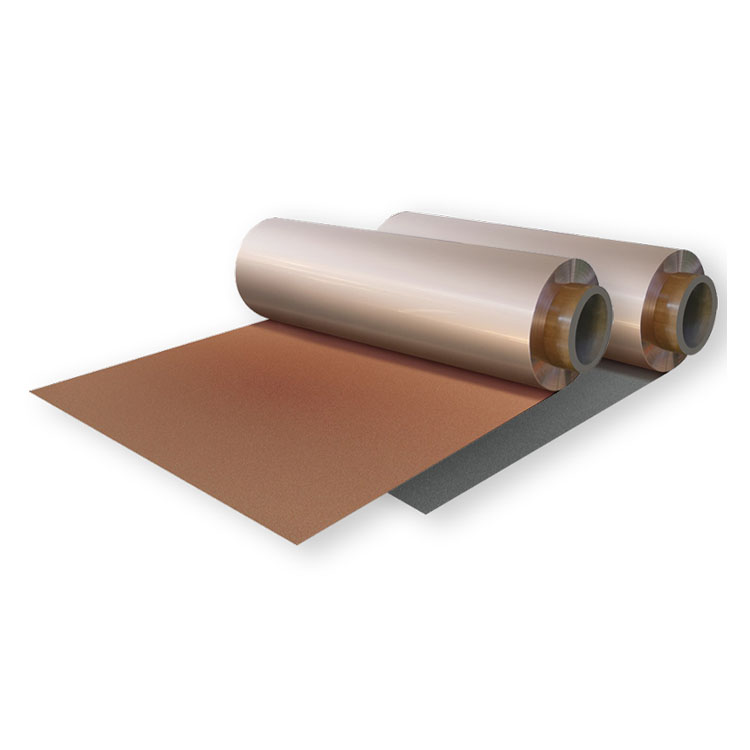

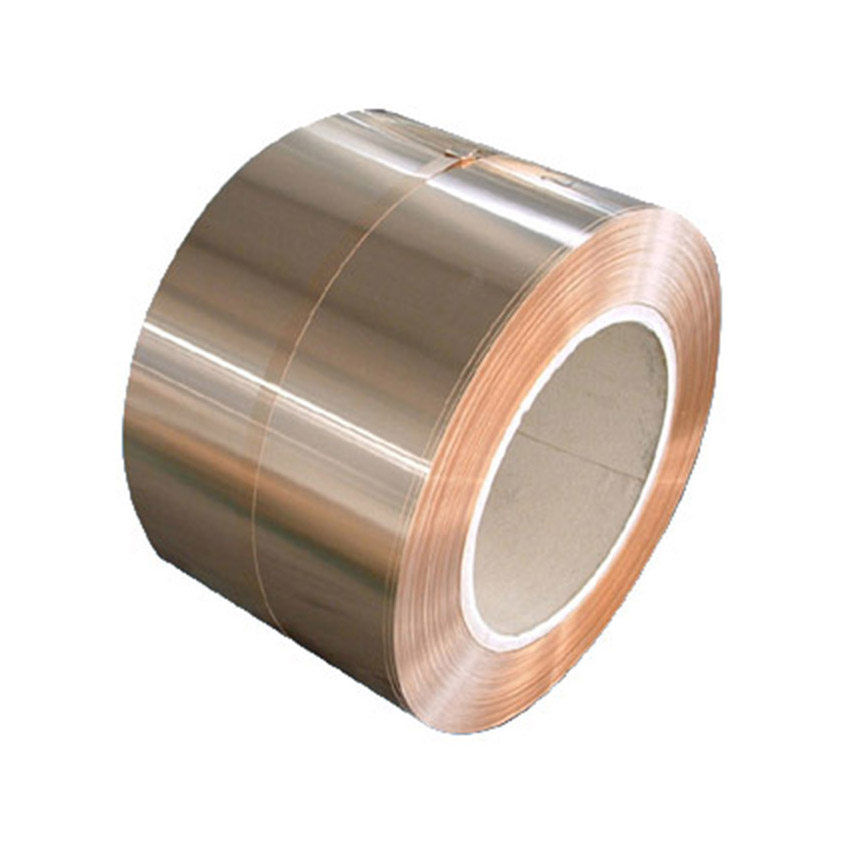

Bronze strip is copper with tin, aluminum, and trace elements as raw materials, through processing by ingots, hot rolled, cold rolled, heat treatment, surface cleaning, cutting, finishing and packing, materials with high yield strength, fatigue strength, elastic properties and excellent bending formability. It has been widely used in computer CPU socket, car terminals, mobile phone keypad, electrical and other high-tech electronics connectors.

Main Technical Parameters

3-1 Chemical Composition

|

Name |

Alloy No. |

Chemical Composition( %,Max.) |

||||||||

|

Sn |

Al |

Zn |

Ni |

Fe |

Pb |

P |

Cu |

Impurity |

||

|

Tin Bronze |

QSn4-0.3 |

3.5-4.9 |

— |

0.30 |

0.2 |

0.10 |

0.05 |

0.03-0.35 |

Rem |

0.2 |

|

QSn4-3 |

3.5-4.5 |

0.002 |

2.7-3.3 |

0.2 |

0.05 |

0.02 |

0.03-0.35 |

Rem |

0.2 |

|

|

QSn6.5-0.1 |

6.0-7.0 |

0.002 |

0.3 |

0.2 |

0.02 |

0.02 |

0.1-0.25 |

Rem |

0.1 |

|

|

QSn8-0.3 |

7.0-9.0 |

—— |

0.2 |

0.2 |

0.10 |

0.05 |

0.03-0.35 |

Rem |

0.1 |

|

|

Aluminum Bronze |

QAl5 |

0.1 |

4.0-6.0 |

0.5 |

0.5 |

0.5 |

0.03 |

0.01 |

Rem |

1.6 |

|

QAl7 |

—– |

6.0-8.5 |

0.2 |

0.5 |

0.5 |

0.02 |

—— |

Rem |

—— |

|

|

QAl9-2 |

0.1 |

8.0-10.0 |

1.0 |

0.5 |

0.5 |

0.03 |

0.01 |

Rem |

1.7 |

|

|

Name |

Alloy No. |

Chemical Composition( %,Max.) |

|||||||||

|

Be |

Al |

Si |

Ni |

Fe |

Pb |

Ti |

Co |

Cu |

Imputrity |

||

|

Beryllium Bronze |

QBe2 |

1.8-2.1 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

— |

— |

Rem |

0.5 |

|

QBe1.9 |

1.85-2.1 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

0.10-0.25 |

— |

Rem |

0.5 |

|

|

QBe1.7 |

1.6-1.85 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

0.10-0.25 |

— |

Rem |

0.5 |

|

|

QBe0.6-2.5 |

0.4-0.7 |

0.20 |

0.20 |

—— |

0.10 |

— |

— |

2.4-2.7 |

Rem |

— |

|

|

QBe0.4-1.8 |

0.2-0.6 |

0.20 |

0.20 |

1.4-2.2 |

0.10 |

— |

— |

0.30 |

Rem |

— |

|

|

QBe0.3-1.5 |

0.25-0.5 |

0.20 |

0.20 |

—— |

0.10 |

— |

— |

1.4-1.7 |

Rem |

— |

|

3-2 Alloy Table

|

Name |

China |

ISO |

ASTM |

JIS |

|

Tin Bronze |

QSn4-0.3 |

CuSn4 |

C51100 |

C5101 |

|

QSn4-3 |

CuSn4Zn2 |

— |

— |

|

|

QSn6.5-0.1 |

CuSn6 |

C51900 |

C5191 |

|

|

QSn8-0.3 |

CuSn8 |

C52100 |

C5210 |

|

|

Aluminum Bronze |

QAl5 |

CuAl5 |

C60600 |

—— |

|

QAl7 |

CuAl7 |

C61000 |

—— |

|

|

QAl9-2 |

CuAl9Mn2 |

—— |

—— |

|

|

Beryllium Bronze |

QBe2 |

CuBe2 |

C17200 |

C1720 |

|

QBe1.9 |

—— |

—— |

—— |

|

|

QBe1.7 |

CuBe1.7 |

C17000 |

C1700 |

|

|

QBe0.6-2.5 |

—— |

C17500 |

C1750 |

|

|

QBe0.4-1.8 |

—— |

C17510 |

C1751 |

|

|

QBe0.3-1.5 |

—— |

C17600 |

C1760 |

Main Technical Parameters

3-3-1Specification Unit: mm

|

Name |

Alloy No.(China) |

Temper |

Size(mm) |

|

|

Thickness |

Width |

|||

|

Tin Bronze Strip |

QSn4-3 QSn4-0.3 QSn6.5-0.1QSn8-0.3 |

O 1/2H H EH |

>0.12~2.0 |

≤600 |

|

O H EH |

||||

|

Aluminum Bronze Strip |

QA15 QA17 QA19-2 |

O H |

>0.2~1.2 |

80~300 |

|

1/2H H |

||||

|

O H EH |

>0.2~1.2 |

80~300 |

||

|

Beryllium Bronze Strip |

QBe2 QBe1.9 QBe1.7 QBe0.6-2.5 QBe0.4-1.8 QBe0.3-1.5 |

O |

0.05-1.5 |

10~340 |

|

H |

||||

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

3-3-2 Tolerance Unit: mm

|

Thickness |

Width |

|||

|

Thickness Allow Deviation± |

Width Allow Deviation ± |

|||

|

<300 |

<600 |

<400 |

<600 |

|

|

0.05~0.1 |

0.005 |

—– |

0.2 |

—– |

|

0.1~0.3 |

0.008 |

0.015 |

0.3 |

0.4 |

|

0.3~0.5 |

0.015 |

0.020 |

0.3 |

0.5 |

|

0.5~0.8 |

0.020 |

0.030 |

0.3 |

0.5 |

|

0.8~1.2 |

0.030 |

0.040 |

0.4 |

0.6 |

3-3-3 Mechanical Performance:

|

Temper |

Tensile Strength N/mm2 |

Elongation ≥% |

Hardness HV |

|

|

M |

(O) |

≥295 |

40 |

—— |

|

Y4 |

(1/4H) |

390-510 |

35 |

100-160 |

|

Y2 |

(1/2H) |

440-570 |

10 |

160-205 |

|

Y |

(H) |

540-690 |

8 |

180-230 |

|

T |

(EH) |

≥640 |

5 |

≥200 |

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for 2021 Good Quality Copper Sheet - Bronze Strip – CIVEN , The product will supply to all over the world, such as: Oman, Islamabad, Cambodia, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.