2021 wholesale price Polished Brass Sheet - Rolled Copper Foils for Battery – CIVEN

2021 wholesale price Polished Brass Sheet - Rolled Copper Foils for Battery – CIVEN Detail:

Product Introduction

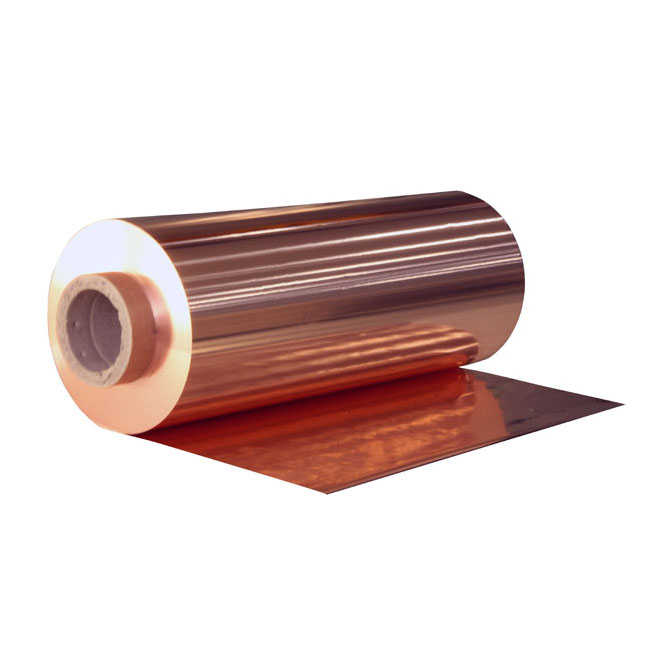

The Battery Rolled Copper Foil is a cathode material produced by CIVEN METAL specifically for high-end batteries. The uniform thickness and flat shape of the copper foil makes it easy to coat and not to peel off; the uniform grain size of the material can effectively increase the charge/discharge times of the battery and reduce battery failure and improve cycle life; the purity of the copper foil is extremely high and it has excellent electrical conductivity; and the rolled copper foil produced by CIVEN METAL has excellent flexibility and hydrophilic. We can also customize our products to meet different customer requirements.

Calendered copper foil is a product made by repeatedly rolling and annealing high-precision copper strip (thickness is usually less than 150 microns) based on the principle of plastic processing (thickness is usually between 4-100 microns and width is usually less than 800 mm). Its ductility, bending resistance and conductivity are better than electrolytic copper foil, and the copper purity is also higher than electrolytic copper foil

Copper foil is an indispensable raw material for making printed circuit board (PCB), copper clad laminate (CCL) and lithium-ion battery. Flexible circuit board is flexible, which gets rid of the limitations of conventional circuit plane design, and can arrange lines in three-dimensional space. Its circuit is more flexible and has higher technical content. Calendered copper foil has become the best choice for manufacturing flexible printed circuit board because of its flexibility and bending resistance.

Specification

Thickness range: 9 ~ 70 μm (0.00035 ~ 0.028 inches)

Width range: 150 ~ 650 mm (5.9 ~ 25.6 inches)

Performance

Comparison for RA & ED copper foil

|

Item |

RA copper foil |

ED copper foil |

|

Craft |

Physical Rolling |

Chemical Electrolysis |

|

Precision |

Very good |

Good |

|

Purity |

Higher |

High |

|

Strength |

Higher |

High |

|

Toughness |

Very Good |

Good |

|

Bendability |

Very Good |

Good |

|

Elasticity |

Higher |

High |

|

Density |

Higher |

High |

|

Tensile |

Higher |

High |

|

Crystal Structure |

Rolling Organization |

Needle-like crystals |

|

Surface |

Shiny |

Matte |

|

Appearance Consistency |

Good |

Good |

Applications

Power batteries, polymer batteries and other battery materials.

Advantage

The material itself has good surface consistency, high elongation, flexibility, uniformity and hydrophilic.

Product detail pictures:

Related Product Guide:

We've got a specialist, effectiveness staff to supply high quality service for our shopper. We always follow the tenet of customer-oriented, details-focused for 2021 wholesale price Polished Brass Sheet - Rolled Copper Foils for Battery – CIVEN , The product will supply to all over the world, such as: Tunisia, Italy, South Africa, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.