Bottom price Flex Ccl - Bronze Strip – CIVEN

Bottom price Flex Ccl - Bronze Strip – CIVEN Detail:

Product Introduction

Bronze strip is copper with tin, aluminum, and trace elements as raw materials, through processing by ingots, hot rolled, cold rolled, heat treatment, surface cleaning, cutting, finishing and packing, materials with high yield strength, fatigue strength, elastic properties and excellent bending formability. It has been widely used in computer CPU socket, car terminals, mobile phone keypad, electrical and other high-tech electronics connectors.

Main Technical Parameters

3-1 Chemical Composition

|

Name |

Alloy No. |

Chemical Composition( %,Max.) |

||||||||

|

Sn |

Al |

Zn |

Ni |

Fe |

Pb |

P |

Cu |

Impurity |

||

|

Tin Bronze |

QSn4-0.3 |

3.5-4.9 |

— |

0.30 |

0.2 |

0.10 |

0.05 |

0.03-0.35 |

Rem |

0.2 |

|

QSn4-3 |

3.5-4.5 |

0.002 |

2.7-3.3 |

0.2 |

0.05 |

0.02 |

0.03-0.35 |

Rem |

0.2 |

|

|

QSn6.5-0.1 |

6.0-7.0 |

0.002 |

0.3 |

0.2 |

0.02 |

0.02 |

0.1-0.25 |

Rem |

0.1 |

|

|

QSn8-0.3 |

7.0-9.0 |

—— |

0.2 |

0.2 |

0.10 |

0.05 |

0.03-0.35 |

Rem |

0.1 |

|

|

Aluminum Bronze |

QAl5 |

0.1 |

4.0-6.0 |

0.5 |

0.5 |

0.5 |

0.03 |

0.01 |

Rem |

1.6 |

|

QAl7 |

—– |

6.0-8.5 |

0.2 |

0.5 |

0.5 |

0.02 |

—— |

Rem |

—— |

|

|

QAl9-2 |

0.1 |

8.0-10.0 |

1.0 |

0.5 |

0.5 |

0.03 |

0.01 |

Rem |

1.7 |

|

|

Name |

Alloy No. |

Chemical Composition( %,Max.) |

|||||||||

|

Be |

Al |

Si |

Ni |

Fe |

Pb |

Ti |

Co |

Cu |

Imputrity |

||

|

Beryllium Bronze |

QBe2 |

1.8-2.1 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

— |

— |

Rem |

0.5 |

|

QBe1.9 |

1.85-2.1 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

0.10-0.25 |

— |

Rem |

0.5 |

|

|

QBe1.7 |

1.6-1.85 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

0.10-0.25 |

— |

Rem |

0.5 |

|

|

QBe0.6-2.5 |

0.4-0.7 |

0.20 |

0.20 |

—— |

0.10 |

— |

— |

2.4-2.7 |

Rem |

— |

|

|

QBe0.4-1.8 |

0.2-0.6 |

0.20 |

0.20 |

1.4-2.2 |

0.10 |

— |

— |

0.30 |

Rem |

— |

|

|

QBe0.3-1.5 |

0.25-0.5 |

0.20 |

0.20 |

—— |

0.10 |

— |

— |

1.4-1.7 |

Rem |

— |

|

3-2 Alloy Table

|

Name |

China |

ISO |

ASTM |

JIS |

|

Tin Bronze |

QSn4-0.3 |

CuSn4 |

C51100 |

C5101 |

|

QSn4-3 |

CuSn4Zn2 |

— |

— |

|

|

QSn6.5-0.1 |

CuSn6 |

C51900 |

C5191 |

|

|

QSn8-0.3 |

CuSn8 |

C52100 |

C5210 |

|

|

Aluminum Bronze |

QAl5 |

CuAl5 |

C60600 |

—— |

|

QAl7 |

CuAl7 |

C61000 |

—— |

|

|

QAl9-2 |

CuAl9Mn2 |

—— |

—— |

|

|

Beryllium Bronze |

QBe2 |

CuBe2 |

C17200 |

C1720 |

|

QBe1.9 |

—— |

—— |

—— |

|

|

QBe1.7 |

CuBe1.7 |

C17000 |

C1700 |

|

|

QBe0.6-2.5 |

—— |

C17500 |

C1750 |

|

|

QBe0.4-1.8 |

—— |

C17510 |

C1751 |

|

|

QBe0.3-1.5 |

—— |

C17600 |

C1760 |

Main Technical Parameters

3-3-1Specification Unit: mm

|

Name |

Alloy No.(China) |

Temper |

Size(mm) |

|

|

Thickness |

Width |

|||

|

Tin Bronze Strip |

QSn4-3 QSn4-0.3 QSn6.5-0.1QSn8-0.3 |

O 1/2H H EH |

>0.12~2.0 |

≤600 |

|

O H EH |

||||

|

Aluminum Bronze Strip |

QA15 QA17 QA19-2 |

O H |

>0.2~1.2 |

80~300 |

|

1/2H H |

||||

|

O H EH |

>0.2~1.2 |

80~300 |

||

|

Beryllium Bronze Strip |

QBe2 QBe1.9 QBe1.7 QBe0.6-2.5 QBe0.4-1.8 QBe0.3-1.5 |

O |

0.05-1.5 |

10~340 |

|

H |

||||

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

3-3-2 Tolerance Unit: mm

|

Thickness |

Width |

|||

|

Thickness Allow Deviation± |

Width Allow Deviation ± |

|||

|

<300 |

<600 |

<400 |

<600 |

|

|

0.05~0.1 |

0.005 |

—– |

0.2 |

—– |

|

0.1~0.3 |

0.008 |

0.015 |

0.3 |

0.4 |

|

0.3~0.5 |

0.015 |

0.020 |

0.3 |

0.5 |

|

0.5~0.8 |

0.020 |

0.030 |

0.3 |

0.5 |

|

0.8~1.2 |

0.030 |

0.040 |

0.4 |

0.6 |

3-3-3 Mechanical Performance:

|

Temper |

Tensile Strength N/mm2 |

Elongation ≥% |

Hardness HV |

|

|

M |

(O) |

≥295 |

40 |

—— |

|

Y4 |

(1/4H) |

390-510 |

35 |

100-160 |

|

Y2 |

(1/2H) |

440-570 |

10 |

160-205 |

|

Y |

(H) |

540-690 |

8 |

180-230 |

|

T |

(EH) |

≥640 |

5 |

≥200 |

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

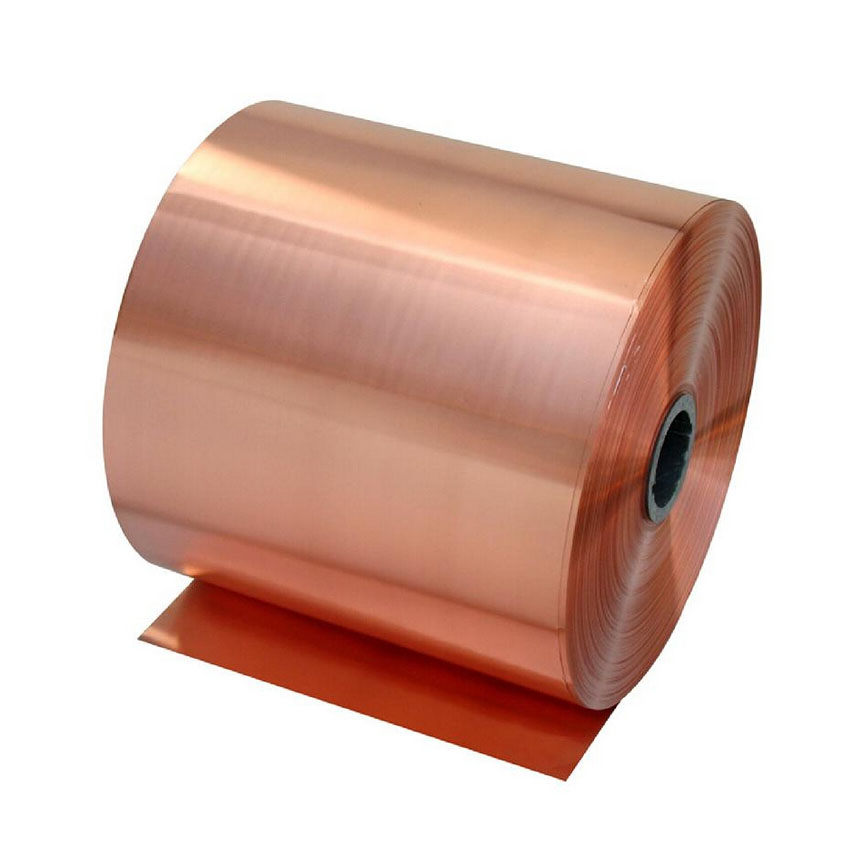

Product detail pictures:

Related Product Guide:

Our primary target will be to provide our clients a serious and responsible small business relationship, supplying personalized attention to all of them for Bottom price Flex Ccl - Bronze Strip – CIVEN , The product will supply to all over the world, such as: Bhutan, New Zealand, Wellington, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.