Low MOQ for Flexible Printed Circuits Copper Foil - Electrolytic Pure NickelFoil – CIVEN

Low MOQ for Flexible Printed Circuits Copper Foil - Electrolytic Pure NickelFoil – CIVEN Detail:

Product Introduction

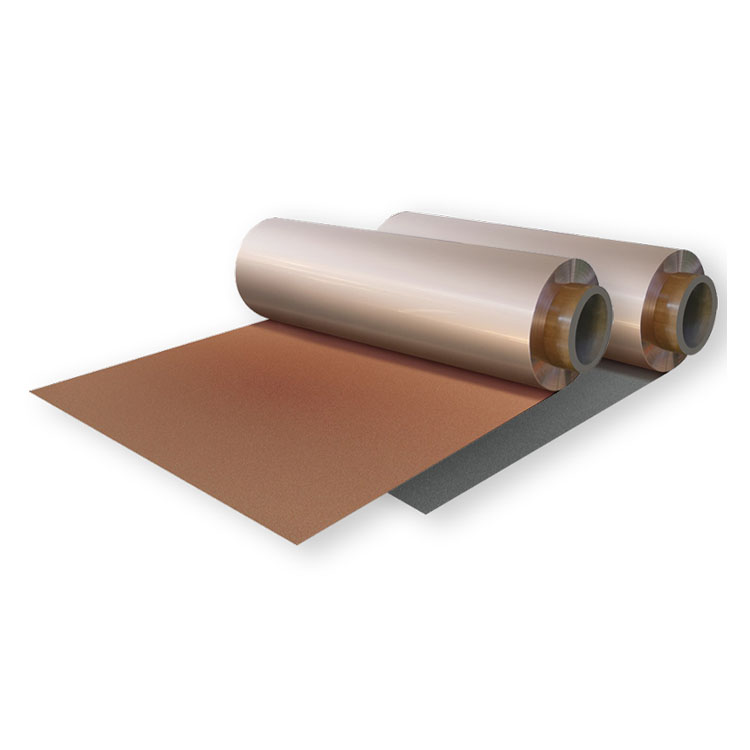

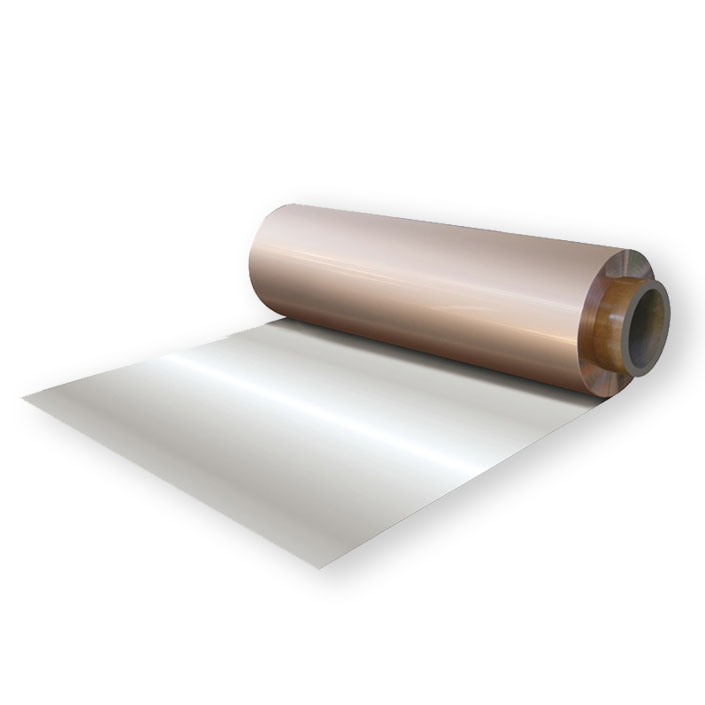

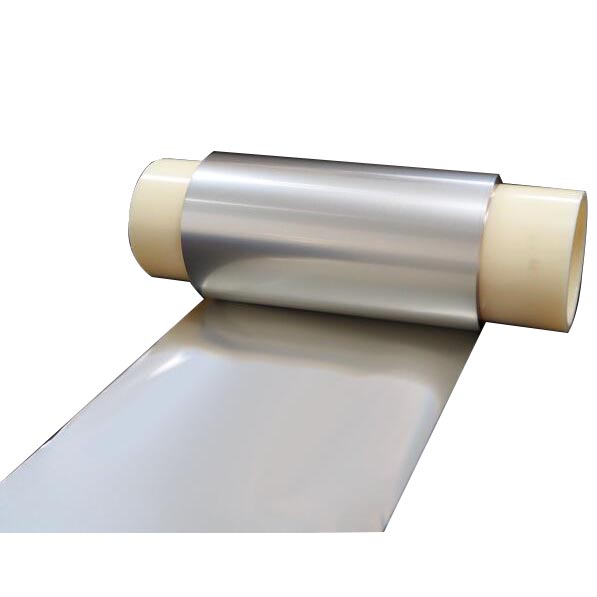

The electrolytic nickel foil produced by CIVEN METAL is based on 1# electrolytic nickel as raw material, using electrolytic method deep processing to extract a foil. The advantages are smooth, clean and flat surface, good ductability, less impurities, high purity, nickel content ≥99%. Because of the high purity, electrolytic nickel foil not only increases the corrosion resistance and but also the shielding performance of the product itself. Electrolytic nickel foil is far wider than rolled nickel foil, increasing the utilization rate of material post-processing. In order to meet customer requirements, pure nickel foil can do surface coarse treatment to increase the adhesion of the product. The roughness can reach more than Ra1.5 μm. Coarsed nickel foil can increase the hydrophilic of the product, greatly improve the adhesion and adsorption performance between nickel foil surface and other materials, can be better with other materials cover synthesis type, not easy to fall off.

Specifications

| Thickness | 5~50(±5%)µm, |

| Width | ≤1330mm |

Performance

● Pure nickel foil is a silver-white metal with a dense surface structure and a high finish

● Tensile Strength: σs=660-1100N/mm²

● Elongation: δ=1.0-10%。

● Electrical Resistivity:0.076Ω·mm² /m

● Average Resistance Temperature Coefficient α=0.006

Application

Widely used in battery components (connecting chips, pole ears, excitation tablets, intercepting tablets), electrical appliances, electric bicycles, laptops, mobile phones, electric vehicles, MP3/MP4, iPAD/IPHONE, digital cameras and video recorders, instrumentation, telecommunications, electric vacuum, special light bulbs, electronic devices anti-corrosion packaging, electronic labels, space thermal control and so on

Advantages

It has excellent mechanical characteristics and high corrosion resistance, qualitative hard, high conductivity, heat resistance, magnetism, low gas volume and low steam pressure, good plasticity and toughness, good stability in water, alkali and various acids in the air.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for Low MOQ for Flexible Printed Circuits Copper Foil - Electrolytic Pure NickelFoil – CIVEN , The product will supply to all over the world, such as: Kenya, Auckland, Argentina, We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!