Manufacturer for Brass Strips - Copper Sheet – CIVEN

Manufacturer for Brass Strips - Copper Sheet – CIVEN Detail:

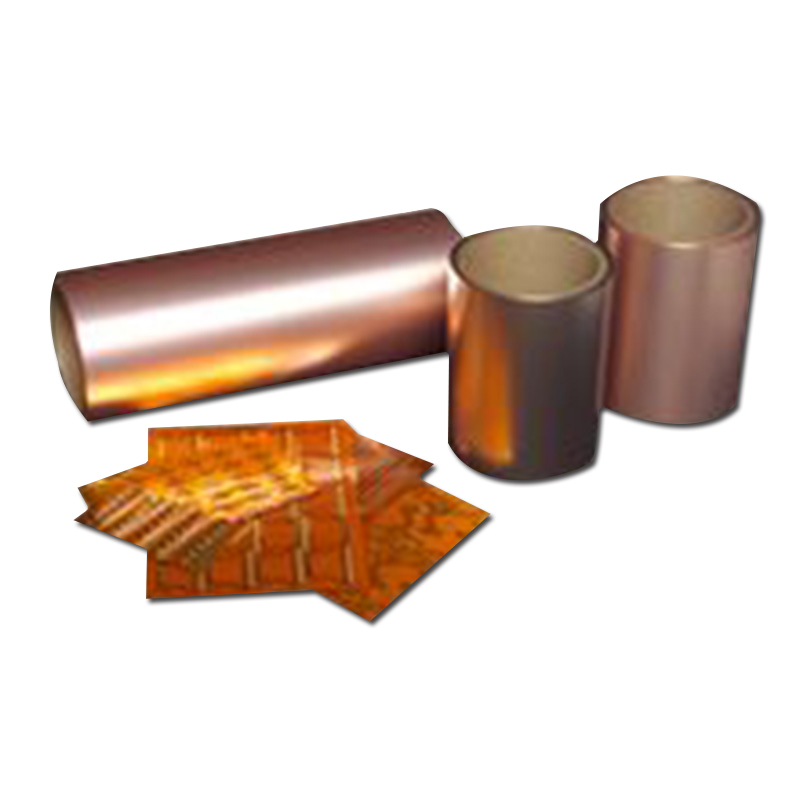

Product Introduction

Copper Sheet is made of electrolytic copper, through processing by ingot, hot rolling, cold rolling, heat treatment, surface cleaning, cutting, finishing, and then packing. The material has excellent thermal and electrical conduction, flexible ductility and good corrosion resistance. It has been widely used in electrical, automotive, communications, hardware, decoration and other industries.

Main Technical Parameters

1-1 Chemical Composition

|

Alloy No. |

Chemical Composition (%,Max.) |

||||||||||||

|

Cu+Ag |

P |

Bi |

Sb |

As |

Fe |

Ni |

Pb |

Sn |

S |

Zn |

O |

Impurity |

|

|

T1 |

99.95 |

0.001 |

0.001 |

0.002 |

0.002 |

0.005 |

0.002 |

0.003 |

0.002 |

0.005 |

0.005 |

0.02 |

0.05 |

|

T2 |

99.90 |

— |

0.001 |

0.002 |

0.002 |

0.005 |

0.005 |

0.005 |

0.002 |

0.005 |

0.005 |

0.06 |

0.1 |

|

TU1 |

99.97 |

0.002 |

0.001 |

0.002 |

0.002 |

0.004 |

0.002 |

0.003 |

0.002 |

0.004 |

0.003 |

0.002 |

0.03 |

|

TU2 |

99.95 |

0.002 |

0.001 |

0.002 |

0.002 |

0.004 |

0.002 |

0.004 |

0.002 |

0.004 |

0.003 |

0.003 |

0.05 |

|

TP1 |

99.90 |

— |

0.002 |

0.002 |

— |

0.01 |

0.004 |

0.005 |

0.002 |

0.005 |

0.005 |

0.01 |

0.1 |

|

TP2 |

99.85 |

— |

0.002 |

0.002 |

— |

0.05 |

0.01 |

0.005 |

0.01 |

0.005 |

— |

0.01 |

0.15 |

1-2 Alloy Table

|

Name |

China |

ISO |

ASTM |

JIS |

|

Pure Copper |

T1,T2 |

Cu-FRHC |

C11000 |

C1100 |

|

oxygen-free copper |

TU1 |

—— |

C10100 |

C1011 |

|

TU2 |

Cu-OF |

C10200 |

C1020 |

|

|

deoxidized copper |

TP1 |

Cu-DLP |

C12000 |

C1201 |

|

TP2 |

Cu-DHP |

C12200 |

C1220 |

1-3 Features

1-3-1Specification mm

|

Name |

Alloy(China) |

Temper |

Size(mm) |

||

|

Thickness |

Width |

Length |

|||

|

Copper Sheet |

T2/TU2 |

H 1/4H |

0.3~0.49 |

600 |

1000~2000 |

|

0.5~3.0 |

600~1000 |

1000~3000 |

|||

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard;R. Hot Rolled.

1-3-2 Tolerance Unit: mm

|

Thickness |

Width |

|||||

|

Thickness Allow Deviation± |

Width Allow Deviation± |

|||||

|

<400 |

<600 |

<1000 |

<400 |

<600 |

<1000 |

|

|

0.5~0.8 |

0.035 |

0.050 |

0.080 |

0.3 |

0.3 |

1.5 |

|

0.8~1.2 |

0.040 |

0.060 |

0.090 |

0.3 |

0.5 |

1.5 |

|

1.2~2.0 |

0.050 |

0.080 |

0.100 |

0.3 |

0.5 |

2.5 |

|

2.0~3.2 |

0.060 |

0.100 |

0.120 |

0.5 |

0.5 |

2.5 |

1-3-3 Mechanical Performance:

|

Alloy |

Temper |

Tensile Strength N/mm2 |

Elongation ≥% |

Hardness HV |

||

|

T1 |

T2 |

M |

(O) |

205-255 |

30 |

50-65 |

|

TU1 |

TU2 |

Y4 |

(1/4H) |

225-275 |

25 |

55-85 |

|

TP1 |

TP2 |

Y2 |

(1/2H) |

245-315 |

10 |

75-120 |

|

|

|

Y |

(H) |

≥275 |

3 |

≥90 |

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard;R. Hot Rolled.

1-3-4 Electrical Parameters:

|

Alloy |

Conductivity/%IACS |

Resistance Coefficient /Ωmm2/m |

|

T1 T2 |

≥98 |

0.017593 |

|

TU1 TU2 |

≥100 |

0.017241 |

|

TP1 TP2 |

≥90 |

0.019156 |

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Manufacturer for Brass Strips - Copper Sheet – CIVEN , The product will supply to all over the world, such as: Plymouth, Maldives, Macedonia, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we will continue with the most professional and high quality service to provide the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!