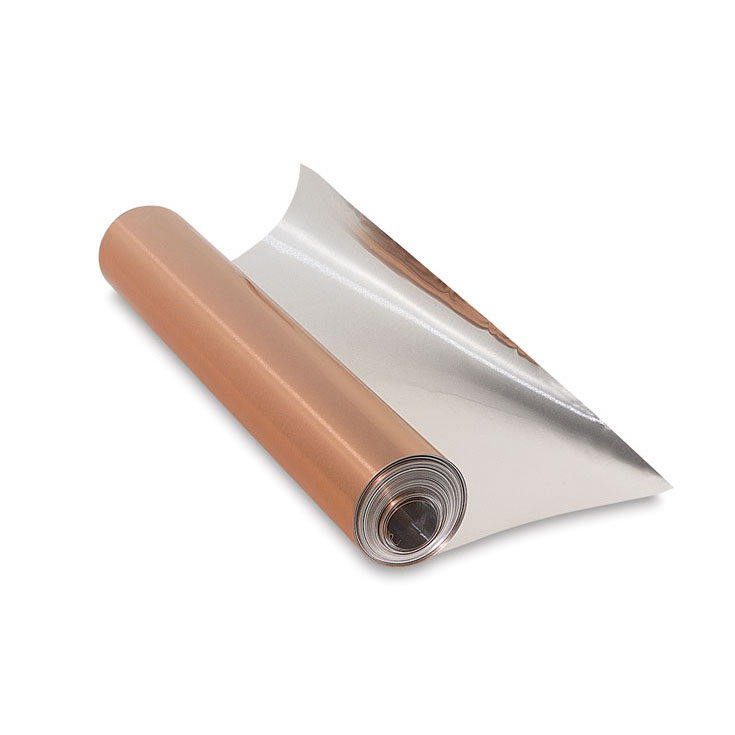

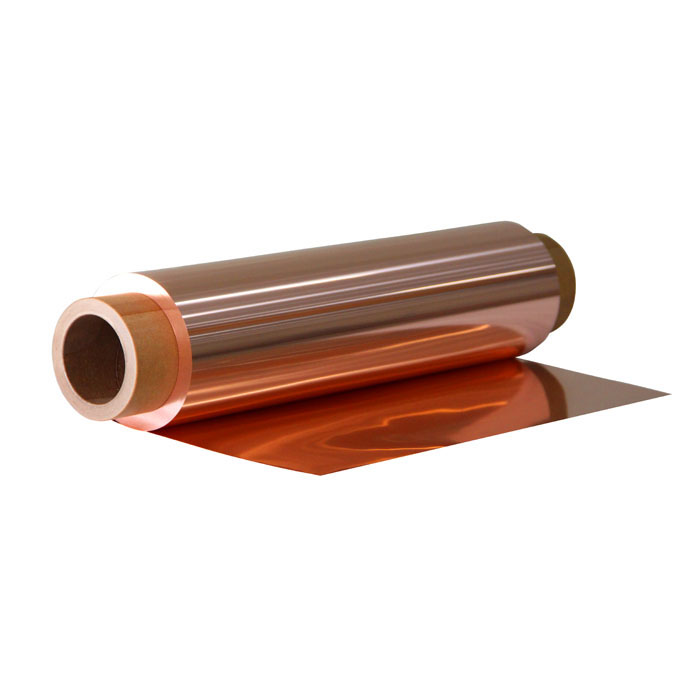

OEM Customized High Temperature And Elongation Copper Foil - High-precision RA Copper Foil – CIVEN

OEM Customized High Temperature And Elongation Copper Foil - High-precision RA Copper Foil – CIVEN Detail:

Product Introduction

High-precision rolled copper foil is a high-quality material produced by CIVEN METAL. Compared to ordinary copper foil products, it has higher purity, better surface finish, better flatness, more precise tolerances and more perfect processing properties. The high precision copper foil has been also degrease and anti-oxidized, which allows the foil to have longer shelf life and be easier to laminate with other materials. As the material is manufactured and packaged in dust free room, the cleanliness of the product is very high and it meets the requirements of a high-end electronics production environment. All of our high precision rolled copper foil products are controlled and monitored according to the strictest international production standards, with the aim of achieving none defect. It can not just be the substitute of the same grade products from Japan and Western Countries, but also shorter the manufacturing period for our customers.

Copper foil is an indispensable raw material for making printed circuit board (PCB), copper clad laminate (CCL) and lithium-ion battery. Industrial copper foil can be divided into calendered copper foil and electrolytic copper foil according to its manufacturing process. Electrolytic copper foil is made by copper electrolysis based on electrochemical principle. The internal structure of the green foil is vertical needle crystal structure, and its production cost is relatively low. Calendered copper foil is formed by repeated rolling annealing process of copper ingot based on the principle of plastic processing. Its internal structure is flake crystalline structure, and the ductility of calendered copper foil products is good. At present, electrolytic copper foil is mainly used in the production of rigid circuit boards, while calendered copper foil is mainly used in flexible and high-frequency circuit boards.

Base Material

● C11000 Copper, Cu > 99.99%

Specifications

● Thickness range: T 0.009 ~ 0.1 mm (0.0003~0.004 inch)

● Width range: W 150 ~ 650.0 mm (5.9 inch~25.6 inch)

Performance

High flexible properties, uniform and flat surface of copper foil, high elongation, good fatigue resistance, strong oxidation resistance and good mechanical properties.

Applications

Suitable for high-end electronic components, circuit boards, batteries, shielding materials, heat dissipation materials and conductive materials

Product detail pictures:

Related Product Guide:

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for OEM Customized High Temperature And Elongation Copper Foil - High-precision RA Copper Foil – CIVEN , The product will supply to all over the world, such as: Cyprus, Egypt, Liberia, We firmly think that we have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.