OEM Factory for Copper Strip Tape - Rolled Copper Foils for Battery – CIVEN

OEM Factory for Copper Strip Tape - Rolled Copper Foils for Battery – CIVEN Detail:

Product Introduction

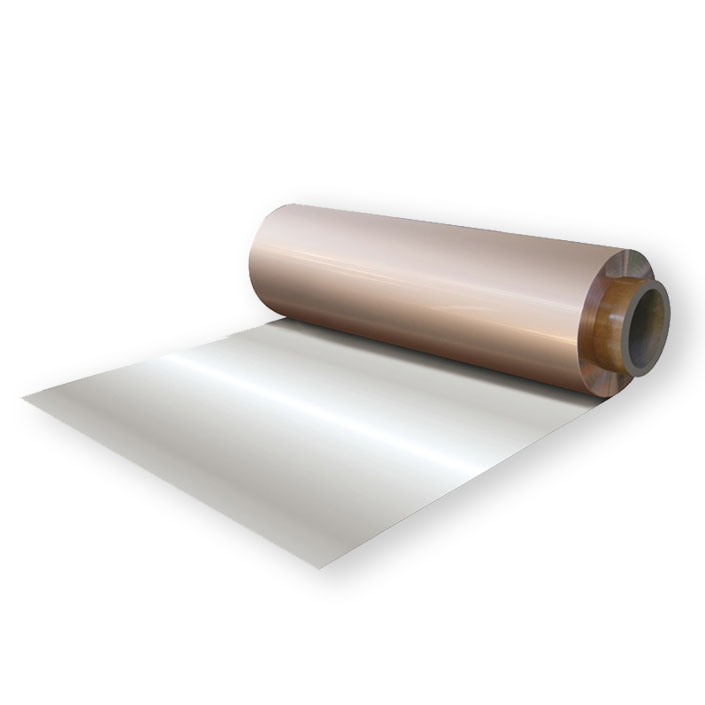

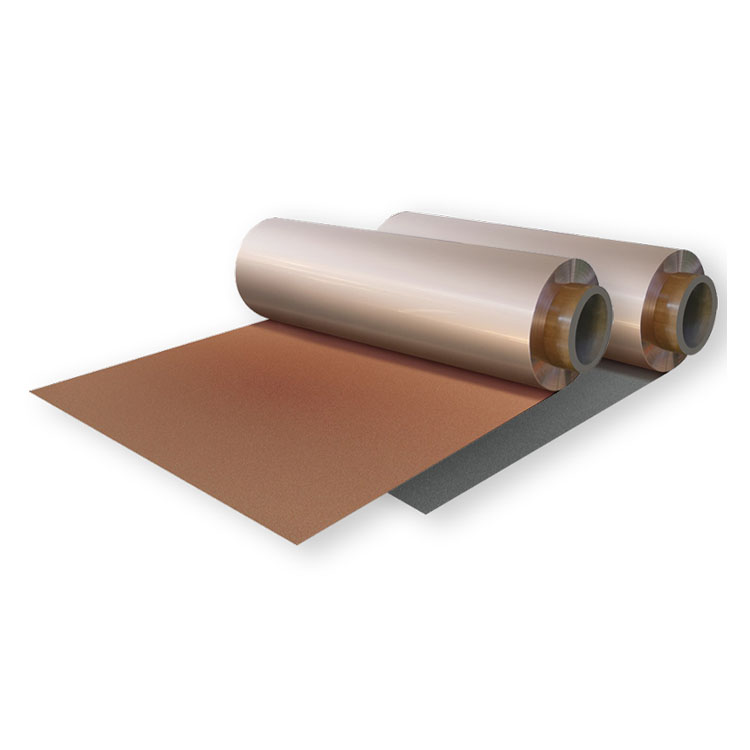

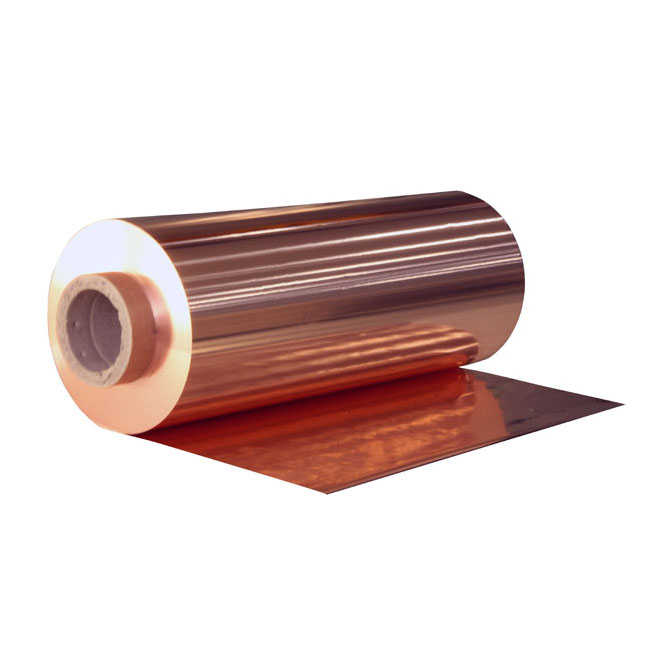

The Battery Rolled Copper Foil is a cathode material produced by CIVEN METAL specifically for high-end batteries. The uniform thickness and flat shape of the copper foil makes it easy to coat and not to peel off; the uniform grain size of the material can effectively increase the charge/discharge times of the battery and reduce battery failure and improve cycle life; the purity of the copper foil is extremely high and it has excellent electrical conductivity; and the rolled copper foil produced by CIVEN METAL has excellent flexibility and hydrophilic. We can also customize our products to meet different customer requirements.

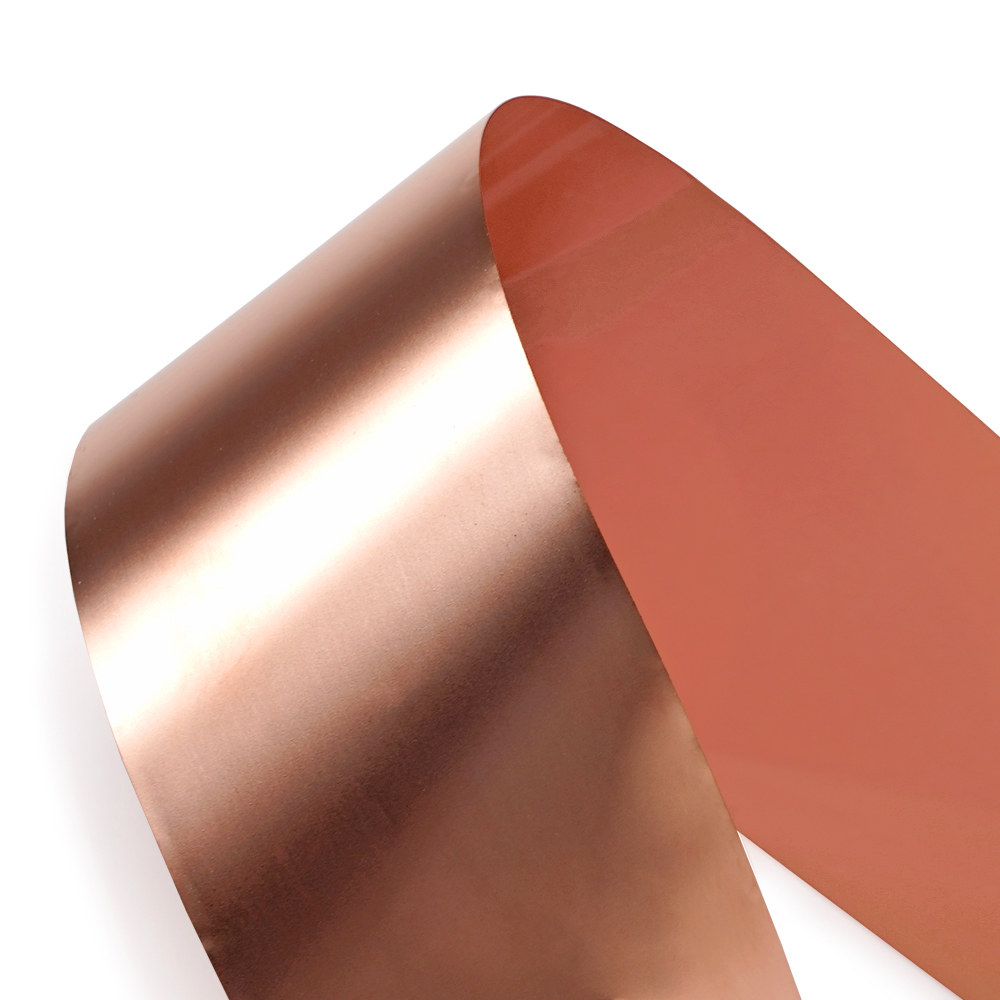

Calendered copper foil is a product made by repeatedly rolling and annealing high-precision copper strip (thickness is usually less than 150 microns) based on the principle of plastic processing (thickness is usually between 4-100 microns and width is usually less than 800 mm). Its ductility, bending resistance and conductivity are better than electrolytic copper foil, and the copper purity is also higher than electrolytic copper foil

Copper foil is an indispensable raw material for making printed circuit board (PCB), copper clad laminate (CCL) and lithium-ion battery. Flexible circuit board is flexible, which gets rid of the limitations of conventional circuit plane design, and can arrange lines in three-dimensional space. Its circuit is more flexible and has higher technical content. Calendered copper foil has become the best choice for manufacturing flexible printed circuit board because of its flexibility and bending resistance.

Specification

Thickness range: 9 ~ 70 μm (0.00035 ~ 0.028 inches)

Width range: 150 ~ 650 mm (5.9 ~ 25.6 inches)

Performance

Comparison for RA & ED copper foil

|

Item |

RA copper foil |

ED copper foil |

|

Craft |

Physical Rolling |

Chemical Electrolysis |

|

Precision |

Very good |

Good |

|

Purity |

Higher |

High |

|

Strength |

Higher |

High |

|

Toughness |

Very Good |

Good |

|

Bendability |

Very Good |

Good |

|

Elasticity |

Higher |

High |

|

Density |

Higher |

High |

|

Tensile |

Higher |

High |

|

Crystal Structure |

Rolling Organization |

Needle-like crystals |

|

Surface |

Shiny |

Matte |

|

Appearance Consistency |

Good |

Good |

Applications

Power batteries, polymer batteries and other battery materials.

Advantage

The material itself has good surface consistency, high elongation, flexibility, uniformity and hydrophilic.

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for OEM Factory for Copper Strip Tape - Rolled Copper Foils for Battery – CIVEN , The product will supply to all over the world, such as: Macedonia, Canada, Thailand, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.