OEM Factory for Sheet Of Tin Foil - VLP ED Copper Foils – CIVEN

OEM Factory for Sheet Of Tin Foil - VLP ED Copper Foils – CIVEN Detail:

Product Introduction

The very low profile electrolytic copper foil produced by CIVEN METAL has the characteristics of low roughness and high peel strength. The copper foil produced by the electrolysis process has the advantages of high purity, low impurities, smooth surface, flat board shape, and large width. The electrolytic copper foil can be better laminated with other materials after roughening on one side, and it is not easy to peel off.

Specifications

CIVEN can provide ultra-low profile high temperature ductile electrolytic copper foil (VLP) from 1/4oz to 3oz (nominal thickness 9µm to 105µm), and the maximum product size is 1295mm x 1295mm sheet copper foil.

Performance

CIVEN provides ultra-thick electrolytic copper foil with excellent physical properties of equiaxial fine crystal, low profile, high strength and high elongation. (See Table 1)

Applications

Applicable to the manufacture of high-power circuit boards and high-frequency boards for automotive, electric power, communication, military and aerospace.

Characteristics

Comparison with similar foreign products.

● The grain structure of our VLP electrolytic copper foil is equiaxed fine crystal spherical; while the grain structure of similar foreign products is columnar and long.

● Electrolytic copper foil is ultra-low profile, 3oz copper foil gross surface Rz ≤5µm; while similar foreign products are standard profile, 3oz copper foil gross surface Rz > 3.5µm.

Advantages

● Since our product is ultra-low profile, it solves the potential risk of the line short circuit due to the large roughness of the standard thick copper foil and the easy penetration of the thin insulation sheet by the “wolf tooth” when pressing the double-sided panel.

● Because the grain structure of our products is equiaxed fine crystal spherical, it shortens the time of line etching and improves the problem of uneven line side etching.

● while having high peel strength, no copper powder transfer, clear graphics PCB manufacturing performance.

Performance(GB/T5230-2000、IPC-4562-2000)

|

Classification |

Unit |

9μm |

12μm |

18μm |

35μm |

70μm |

105μm |

|

|

Cu Content |

% |

≥99.8 |

||||||

|

Area Weigth |

g/m2 |

80±3 |

107±3 |

153±5 |

283±7 |

585±10 |

875±15 |

|

|

Tensile Strength |

R.T.(23℃) |

Kg/mm2 |

≥28 |

|||||

|

H.T.(180℃) |

≥15 |

≥18 |

≥20 |

|||||

|

Elongation |

R.T.(23℃) |

% |

≥5.0 |

≥6.0 |

≥10 |

|||

|

H.T.(180℃) |

≥6.0 |

≥8.0 |

||||||

|

Roughness |

Shiny(Ra) |

μm |

≤0.43 |

|||||

|

Matte(Rz) |

≤3.5 |

|||||||

|

Peel Strength |

R.T.(23℃) |

Kg/cm |

≥0.77 |

≥0.8 |

≥0.9 |

≥1.0 |

≥1.5 |

≥2.0 |

|

Degraded rate of HCΦ(18%-1hr/25℃) |

% |

≤7.0 |

||||||

|

Change of color(E-1.0hr/200℃) |

% |

Good |

||||||

|

Solder Floating 290℃ |

Sec. |

≥20 |

||||||

|

Appearance(Spot and copper powder) |

—- |

None |

||||||

|

Pinhole |

EA |

Zero |

||||||

|

Size Tolerance |

Width |

mm |

0~2mm |

|||||

|

Length |

mm |

—- |

||||||

|

Core |

Mm/inch |

Inside Diameter 79mm/3 inch |

||||||

Note: 1. The Rz value of copper foil gross surface is the test stable value, not a guaranteed value.

2. Peel strength is the standard FR-4 board test value (5 sheets of 7628PP).

3. Quality assurance period is 90 days from the date of receipt.

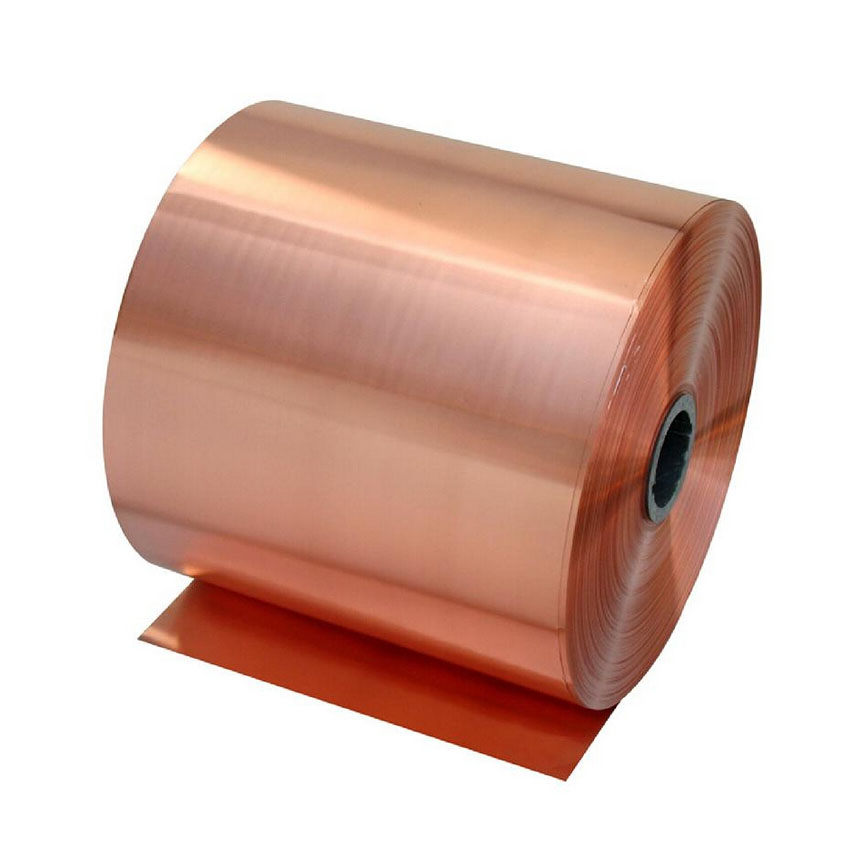

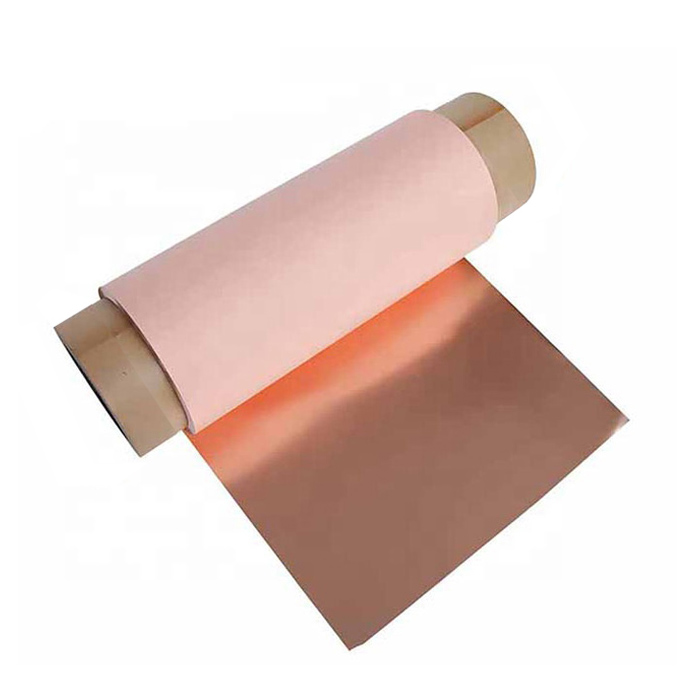

Product detail pictures:

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for OEM Factory for Sheet Of Tin Foil - VLP ED Copper Foils – CIVEN , The product will supply to all over the world, such as: Kuala Lumpur, Uganda, Somalia, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.