Short Lead Time for Battery Copper Foil - Copper Strip – CIVEN

Short Lead Time for Battery Copper Foil - Copper Strip – CIVEN Detail:

Product Introduction

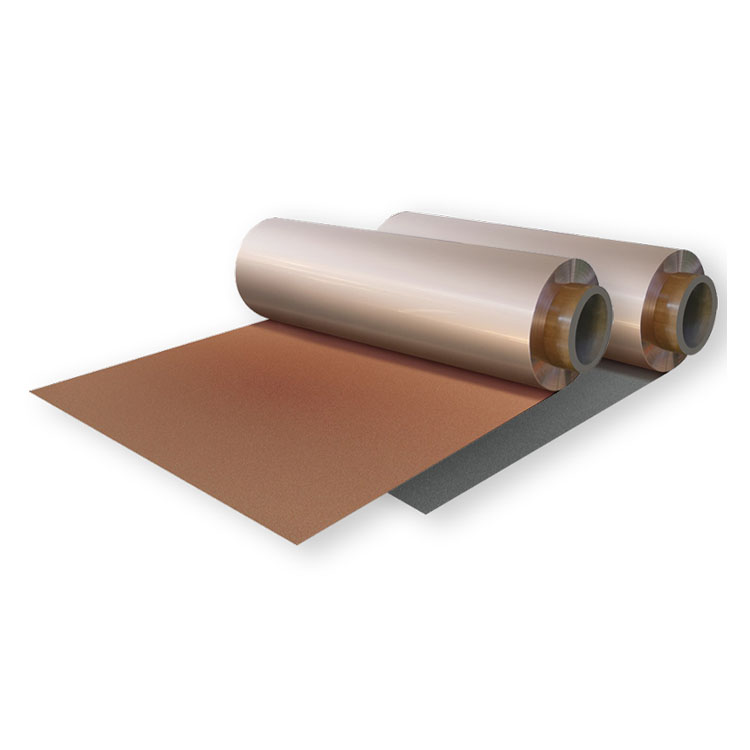

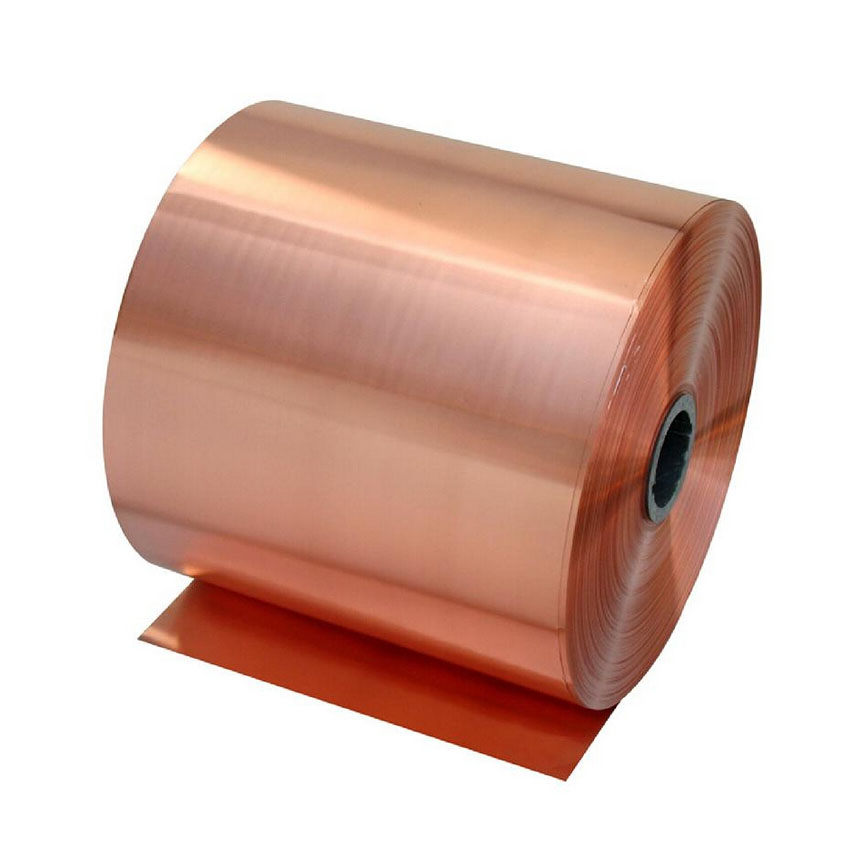

Copper strip is made of electrolytic copper, through processing by ingot, hot rolling, cold rolling, heat treatment, surface cleaning, cutting, finishing, and then packing.

The material has excellent thermal and electrical conduction, flexible ductility and good corrosion resistance. It has been widely used in electrical, automotive, communications, hardware, decoration and other industries.

Our company developed a product range for special-use, such as dry-type transformers strips, the RF coaxial cable strips, shield strips to wire and cable, lead frame materials, punching strips for electronics, solar photovoltaic ribbons, water-stop strips in construction, decorated with bronze doors, composite materials, car tank strips, radiator strips, etc.

Main Technical Parameters

Chemical Composition

|

Alloy No. |

Chemical Composition( %,Max.) |

||||||||||||

|

Cu+Ag |

P |

Bi |

Sb |

As |

Fe |

Ni |

Pb |

Sn |

S |

Zn |

O |

impurity |

|

|

T1 |

99.95 |

0.001 |

0.001 |

0.002 |

0.002 |

0.005 |

0.002 |

0.003 |

0.002 |

0.005 |

0.005 |

0.02 |

0.05 |

|

T2 |

99.90 |

— |

0.001 |

0.002 |

0.002 |

0.005 |

0.005 |

0.005 |

0.002 |

0.005 |

0.005 |

0.06 |

0.1 |

|

TU1 |

99.97 |

0.002 |

0.001 |

0.002 |

0.002 |

0.004 |

0.002 |

0.003 |

0.002 |

0.004 |

0.003 |

0.002 |

0.03 |

|

TU2 |

99.95 |

0.002 |

0.001 |

0.002 |

0.002 |

0.004 |

0.002 |

0.004 |

0.002 |

0.004 |

0.003 |

0.003 |

0.05 |

|

TP1 |

99.90 |

— |

0.002 |

0.002 |

— |

0.01 |

0.004 |

0.005 |

0.002 |

0.005 |

0.005 |

0.01 |

0.1 |

|

TP2 |

99.85 |

— |

0.002 |

0.002 |

— |

0.05 |

0.01 |

0.005 |

0.01 |

0.005 |

— |

0.01 |

0.15 |

Alloy Table

|

Name |

China |

ISO |

ASTM |

JIS |

|

Pure Copper |

T1,T2 |

Cu-FRHC |

C11000 |

C1100 |

|

oxygen-free copper |

TU1 |

—— |

C10100 |

C1011 |

|

TU2 |

Cu-OF |

C10200 |

C1020 |

|

|

deoxidized copper |

TP1 |

Cu-DLP |

C12000 |

C1201 |

|

TP2 |

Cu-DHP |

C12200 |

C1220 |

Features

1-3-1 Specification mm

|

Name |

Alloy(China) |

Temper |

Size(mm) |

|

|

Thickness |

Width |

|||

|

Copper Strip |

T1 T2 TU1 TU2 TP1 TP2 |

H 1/2H |

0.05~0.2 |

≤600 |

|

0.2~0.49 |

≤800 |

|||

|

0.5~3.0 |

≤1000 |

|||

|

Shield Strip |

T2 |

O |

0.05~0.25 |

≤600 |

|

O |

0.26~0.8 |

≤800 |

||

|

Cable Strip |

T2 |

O |

0.25~0.5 |

4~600 |

|

Transformer Strip |

TU1 T2 |

O |

0.1~<0.5 |

≤800 |

|

0.5~2.5 |

≤1000 |

|||

|

Radiator Strip |

TP2 |

O 1/4H |

0.3~0.6 |

15~400 |

|

PV Ribbon |

TU1 T2 |

O |

0.1~0.25 |

10~600 |

|

Car Tank Strip |

T2 |

H |

0.05~0.06 |

10~600 |

|

Decoration Strip |

T2 |

H O |

0.5~2.0 |

≤1000 |

|

Water-Stop Strip |

T2 |

O |

0.5~2.0 |

≤1000 |

|

Lead Frame Materials |

LE192 LE194 |

H 1/2H 1/4H EH |

0.2~1.5 |

20~800 |

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

1-3-2 Tolerance Unit: mm

|

Thickness |

Width |

|||||

|

Thickness Allow Deviation± |

Width Allow Deviation± |

|||||

|

<600 |

<800 |

<1000 |

<600 |

<800 |

<1000 |

|

|

0.1~0.3 |

0.008 |

0.015 |

—– |

0.3 |

0.4 |

—– |

|

0.3~0.5 |

0.015 |

0.020 |

—– |

0.3 |

0.5 |

—– |

|

0.5~0.8 |

0.020 |

0.030 |

0.060 |

0.3 |

0.5 |

0.8 |

|

0.8~1.2 |

0.030 |

0.040 |

0.080 |

0.4 |

0.6 |

0.8 |

|

1.2~2.0 |

0.040 |

0.045 |

0.100 |

0.4 |

0.6 |

0.8 |

1-3-3 Mechanical Performance:

|

Alloy |

Temper |

Tensile Strength N/mm2 |

Elongation ≥% |

Hardness HV |

||

|

T1 |

T2 |

M |

(O) |

205-255 |

30 |

50-65 |

|

TU1 |

TU2 |

Y4 |

(1/4H) |

225-275 |

25 |

55-85 |

|

TP1 |

TP2 |

Y2 |

(1/2H) |

245-315 |

10 |

75-120 |

|

|

|

Y |

(H) |

≥275 |

3 |

≥90 |

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

1-3-4 Electrical Parameter:

|

Alloy |

Conductivity/% IACS |

Resistance Coefficient /Ωmm2/m |

|

T1 T2 |

≥98 |

0.017593 |

|

TU1 TU2 |

≥100 |

0.017241 |

|

TP1 TP2 |

≥90 |

0.019156 |

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product quality is base of enterprise survival; customer satisfaction is the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff" and the consistent purpose of "reputation first, customer first" for Short Lead Time for Battery Copper Foil - Copper Strip – CIVEN , The product will supply to all over the world, such as: London, Croatia, Italy, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary items we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.