Short Lead Time for Battery Copper Foil - Wholesale Price China Pure Tungsten Bar Rods&Tungsten Carbide Rods Used in High-Temperature Sapphire Furnace – CIVEN

Short Lead Time for Battery Copper Foil - Wholesale Price China Pure Tungsten Bar Rods&Tungsten Carbide Rods Used in High-Temperature Sapphire Furnace – CIVEN Detail:

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers’ demands for Wholesale Price China Pure Tungsten Bar Rods&Tungsten Carbide Rods Used in High-Temperature Sapphire Furnace, We welcome new and old customers from all walks of life to contact us for future business relationships and achieve mutual success!

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers’ demands for China Tungsten Rods, High Purity Tungsten Rods, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

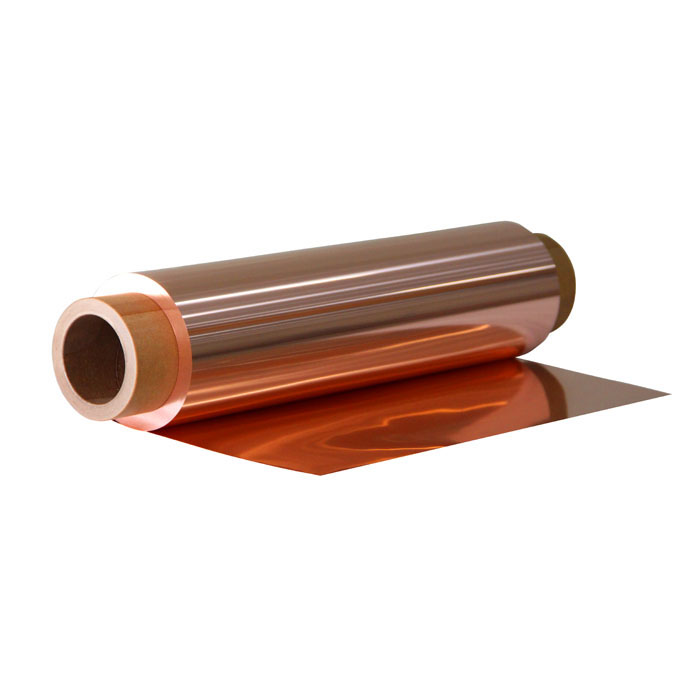

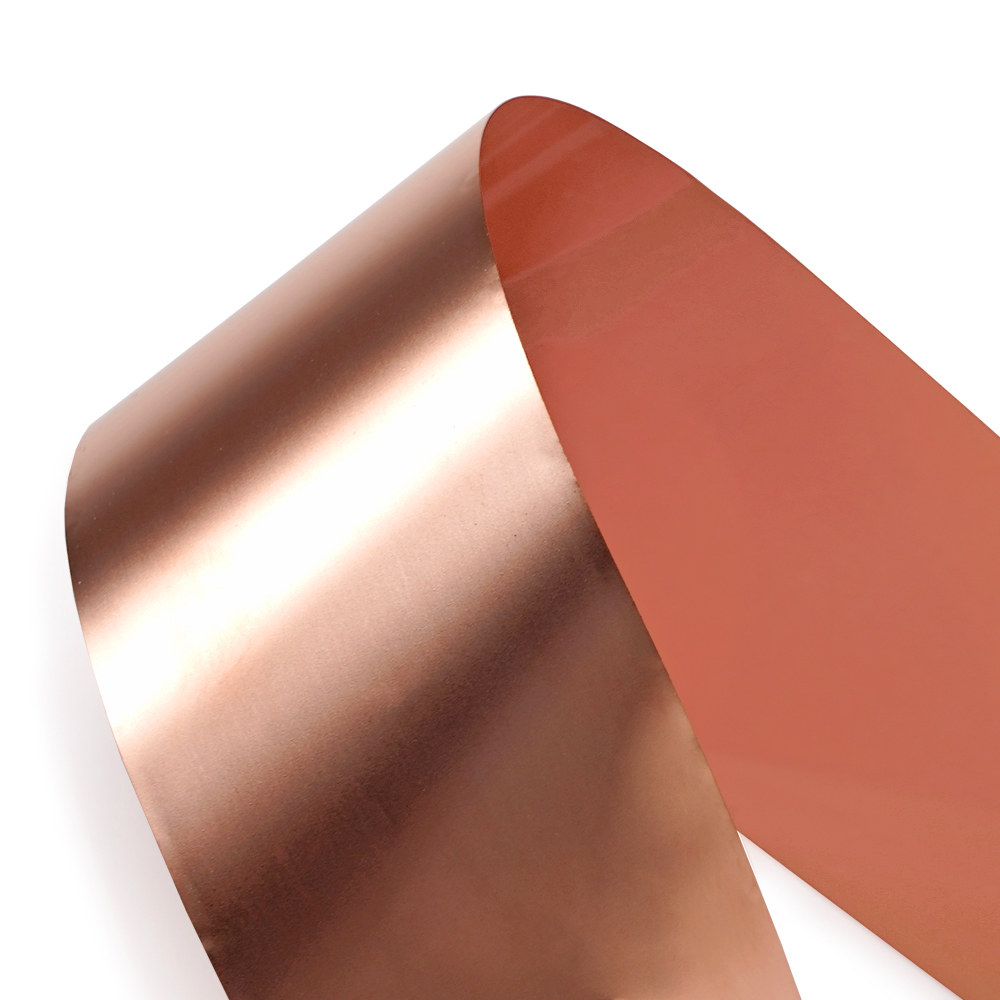

Product Introduction

Beryllium Copper Foil is one kind of supersaturated solid solution copper alloy which combined very good mechanical ,physical, chemical properties and corrosion resistance. It has high intensity limit, elastic limit, yield strength and fatigue limit as special steel after solution treatment and aging. It also has high conductivity, thermal conductivity, high hardness and wear resistance, high creep resistance and corrosion resistance for which it has been widely used to replace steel in the manufacturing of various types of mold inserts, producing precision and complex shaped molds, welding electrode material casting machines, injecting molding machines’ punches and etc.

Beryllium Copper Foil’s application is micro-motor brush, cell phone batteries, computer connectors, all kinds of switch contacts, springs, clips, gaskets, diaphragms, film and etc.

It is indispensable an important industrial material to the national economy

Beryllium bronze is a precipitation hardening alloy. After solution aging treatment, it has high strength, hardness, elastic limit and fatigue limit, small elastic lag, corrosion resistance and machining performance. Beryllium copper alloy is the material of submarine cable repeater structure, which is characterized by low temperature resistance, non magnetism, high electrical conductivity, impact and no spark. At the same time, it also has good fluidity and the ability to reproduce fine patterns. Beryllium copper alloy has been widely used in manufacturing industry because of its many superior properties. Strong conductivity, low temperature resistance, non-magnetic, high conductivity, impact and no spark. At the same time, it also has good fluidity and the ability to reproduce fine patterns.

Contents

|

Alloy No. |

Main Chemical Composition |

|||

|

ASTM |

Cu |

Ni |

Co |

Be |

|

C17200 |

Remin |

① |

① |

1.80-2.10 |

“①”:Ni+Co≥0.20%; Ni+Fe+Co≤0.60%;

Properties

| Density | 8.6g/cm3 |

| Hardness | 36-42HRC |

| Conductivity | ≥18%IACS |

| Tensile strength | ≥1100Mpa |

| Thermal Conductivity | ≥105w/m.k20℃ |

Specification

| Type | Coils and Sheets |

| Thickness | 0.02~0.1mm |

| Width | 1.0~625mm |

| Tolerance in thickness and width | According to standard YS/T 323-2002 or ASTMB 194-96. |

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers’ demands for Wholesale Price China Pure Tungsten Bar Rods&Tungsten Carbide Rods Used in High-Temperature Sapphire Furnace, We welcome new and old customers from all walks of life to contact us for future business relationships and achieve mutual success!

Wholesale Price China Tungsten Rods, High Purity Tungsten Rods, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency revenue team values customers' wants and company communication for Short Lead Time for Battery Copper Foil - Wholesale Price China Pure Tungsten Bar Rods&Tungsten Carbide Rods Used in High-Temperature Sapphire Furnace – CIVEN , The product will supply to all over the world, such as: Bandung, Macedonia, Dubai, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!